How do I factor in forecast accuracy, supplier lead times and variability, service level targets and order cycle periods into my safety stock calculations?

The Perils of Overly Simple Approaches

Many ERP packages employ some very simple techniques to handle what are unfortunately very complex issues.

| Technique |

Risks inherent in too simple an approach |

| Days (or Months) of Cover |

Many packages ask ‘Well how long will I have to protect myself against sales or supply variability?’ They come up with strategies like … ‘If I have 30 days of stock then I should be safe.’

One problem with this sort of strategy is that it does not handle very low sales rate products at all well. Stocking 30 days of product translates to no stock at all typically for a product that is sold perhaps at 0.25 units per month. If it sells at 0.6 per month, then you might stock one, but this then ignores the fact the item is sold in twos. |

| Cover forecast variability but then add another couple of weeks to cover supply variability |

Probably a better approach but it still suffers from similar issues to the simple ‘days of cover’ model. If you add another couple of weeks to cover supply variability does that cover you for when the supplier shuts down over Chinese New Year or the Italian summer holidays. If that were at the height of the season then you might have a significant problem with your safety stock. And if you discover you have a supply problem, it is too late to order more safety stock at that point. Safety stock has to be ordered in advance of when you might need it, and for a seasonal product that might mean building your safety stock with purchases during the seasonal trough. |

Comprehensive Solutions are needed

To handle supply planning properly you need to consider all the relevant factors.

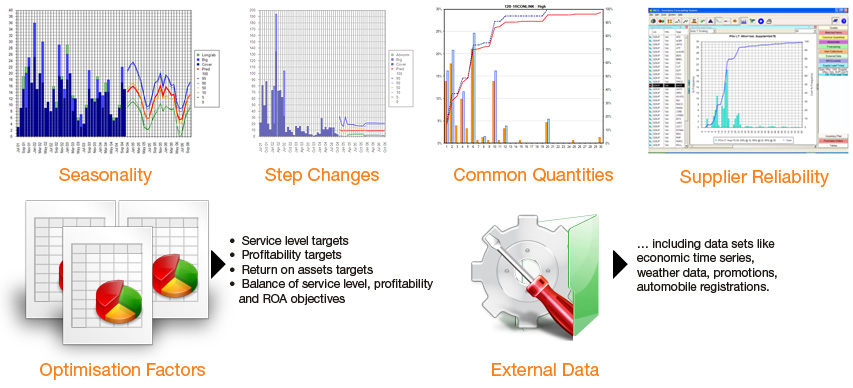

Realistically it would be virtually impossible to consider all the factors that micq-if takes into account when preparing a supply plan. Things like:

Status of downstream warehouses (excess or deficit)

… and there are more factors like forward and back orders, display stock, costs (product, ordering, carrying), product popularity and risk profiles, shelf life, excess elsewhere in the network, changes in expected arrival of incoming supply, supplier and local holidays … all up, rather more than you can reasonably take into consideration with a simple ‘in the head’ or ‘days of cover’ type calculation. Rather than making overly simplistic assumptions, micq-if recognises that supply planning is often difficult and complex. micq-if can integrate the different factors, and help you arrive at a much more considered position on what your safety stock and supply plan position should be.

With micq-if you can spend less time on individual supply transactions and more on setting the overall policies and parameters which control the way your supply plans operate.