|

Managing Run Rates, in the February 2020 Edition

What have one day and T20 cricket got in common with effective inventory management? As it happens, a lot. Read more on how to manage your run rates in article number 50.

Click to view

|

|

Inventory Management In A Changing Climate, in the November 2019 Edition

Confronting climate change is in the news and how to respond from an inventory management point of view is explored in this month’s article.

Click to view

|

|

Support Warehouses, in the October 2019 Edition

It is a lot easier to deliver good service levels when you can draw on good backup. This article describes how you can easily implement a support warehouse network to increase service levels while containing the overall inventory investment.

Click to view

|

|

Trust your Tools, in the September 2019 Edition

The September article will help confront the reluctance we often face when using new tools and why sometimes we just need to trust them. Just think of how the humble mobile phone has changed our lives and given us new opportunities. The same is true for inventory management systems that can help you find a totally new way of getting to where you need to get. Find out more in this month’s article.

Click to view

|

|

Any Interest in Inventory, in the August 2019 Edition

Low interest rates might suggest you can have less focus on funding inventory. However this might be the very time when more focus is needed. Think about your strategy as you read this month’s article.

Click to view

|

|

Lose Your Inventory Inhibitions, in the July 2019 Edition

Inventory management is often about managing risk, and many inventory planners adopt a risk averse and conservative posture. However there are times when it might be wise to embrace a much more optimistic and even riskier position. Is it time you lost some of your inventory inhibitions? Walk a little on the wild side with this month’s article.

Click to view

|

|

Two Moves Ahead, in the June 2019 Edition

Remember when you used to play chess. Remember those times when you played your brother or sister, or even the first time you beat your Dad. One of the things you learned early was that to play well you had to think ahead, at least two moves, and although it could do your head in, more if you could. Inventory management is in many ways just like a game of chess. To play well you do have to think several moves ahead. Be aware of your situation. Have you got plenty of stock, or are you constrained and you will have to move each piece of stock ever so carefully? Are some pieces of stock more important than others? Should they be moved differently? Why? How? Find out more in the June article.

Click to view

|

|

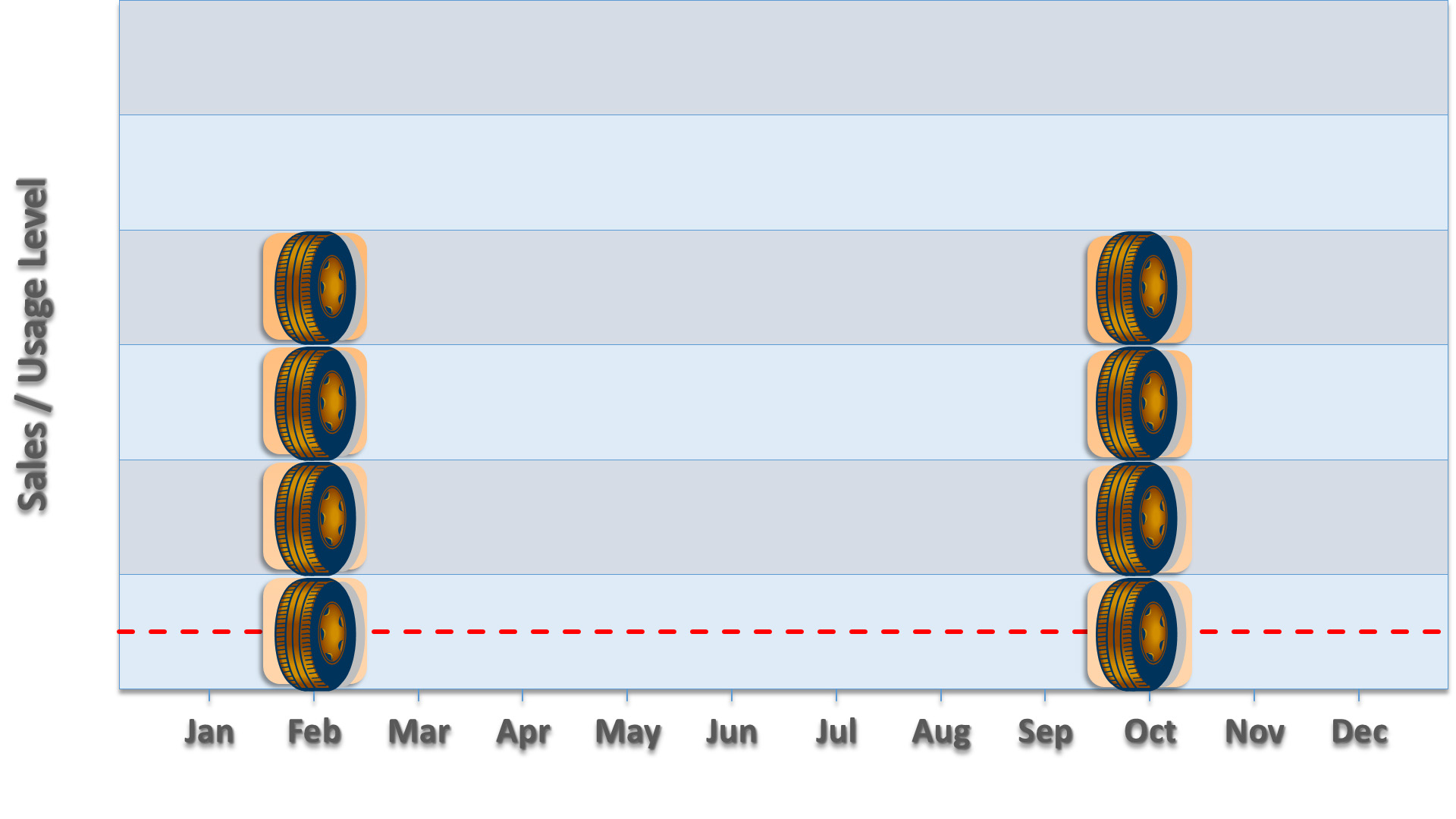

Time For Supplier Alignment?, in the May 2019 Edition

Bad wheel alignment can scrub out tyres and compromise safety, quite apart from the damage to your bank balance, having to replace tyres prematurely. The problem of course is that by the time you can see the damage, it is too late. You need to be proactive. You need to measure and adjust and periodically recheck. Poor supplier alignment can have the same sort of effect. Not surprisingly however the recipe to keeping things on track is quite similar, and involves measurement and adjustment too. Find out more in the May article.

Click to view

|

|

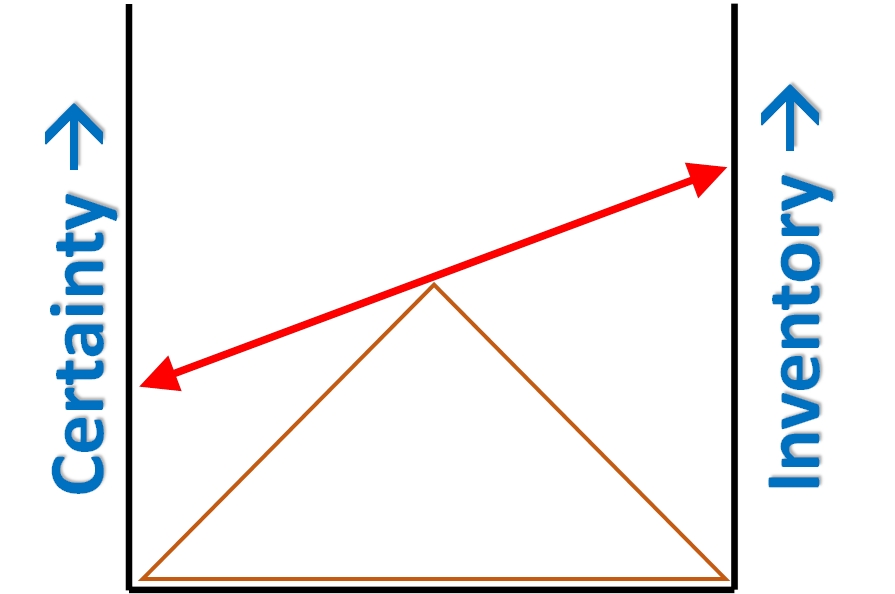

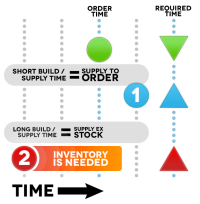

The Certainty Principle, in the March 2019 Edition

If you have a perfect view of demand i.e. you are totally certain, and you know exactly when stock will be delivered if ordered today, even in one hundred days, then the amount of safety stock you need is ZERO. Unfortunately we do not live in a perfect world. There is nearly always some degree of uncertainty, and therefore you need to increase your safety stock to compensate. Importantly however you can work on increasing the certainty with which you 'know' key variables, then you can reduce the level of inventory needed for the desired service level. In this article, entitled The Certainty Principle, Mark Watson, Group Forecasting and Planning Manager for Inenco explores some of his strategies to improve certainty, improve service levels and reduce stock levels.

Click to view

|

|

Need More Hands, in the February 2019 Edition

There are times when it all seems too much. Oh, for another set of hands. With inventory management unfortunately it is all too easy to have our hands full. Maybe it is time to step back and understand what is driving all the workload. Find out more in this month’s article.

Click to view

|

|

Stretching Every Dollar Further, in the November 2018 Edition

The aftermarket is characterised by a lot of inherently slower moving inventory. It is all too easy to get it wrong and to have your cashflow stall and your working capital engine grind to an expensive halt. We have to be forever vigilant to stretch every dollar as far we can, to maximise the returns achieved from our inventory investment. Consider how you might stretch every dollar further and read the November article.

Click to view

|

|

Maximising Your Service Levels, in the October 2018 Edition

How hard are you pushing your service levels? How hard could you push them? Well if marketing decides how far to push service levels then 100% might well be the objective. But of course we all know that that could easily create horrendously high inventory levels too. Not that smart at all. But maybe you could get very close to 100% with some smart strategies. Find out more in this month’s article.

Click to view

|

|

Pick a Degree Of Difficulty And Execute Well, in the September 2018 Edition

Champion divers go for that bit more than the rest of the pack and then execute better too. They choose to do what others regard as complex or difficult and make it look easy. The same is true of the best inventory management practices. So if you want to produce a top performance aim to incorporate all the best approaches into your repertoire and execute at a consistently high standard. With some help you can also make it look effortless too. Find out more in this month’s article.

Click to view

|

|

Proactive Better Than Reactive, in the August 2018 Edition

We all know that when you are driving, to drive faster and to drive safely it is important to set up well in advance of the corner. You need to brake at the right time, steer for the apex and then you can accelerate out of the corner. Preparation is key. Inventory management is much the same. You don't want to make decisions too late and damage your supply chain or your business. Ideally you need to think well ahead and set up for each stock move. Find out more in this month’s article.

Click to view

|

|

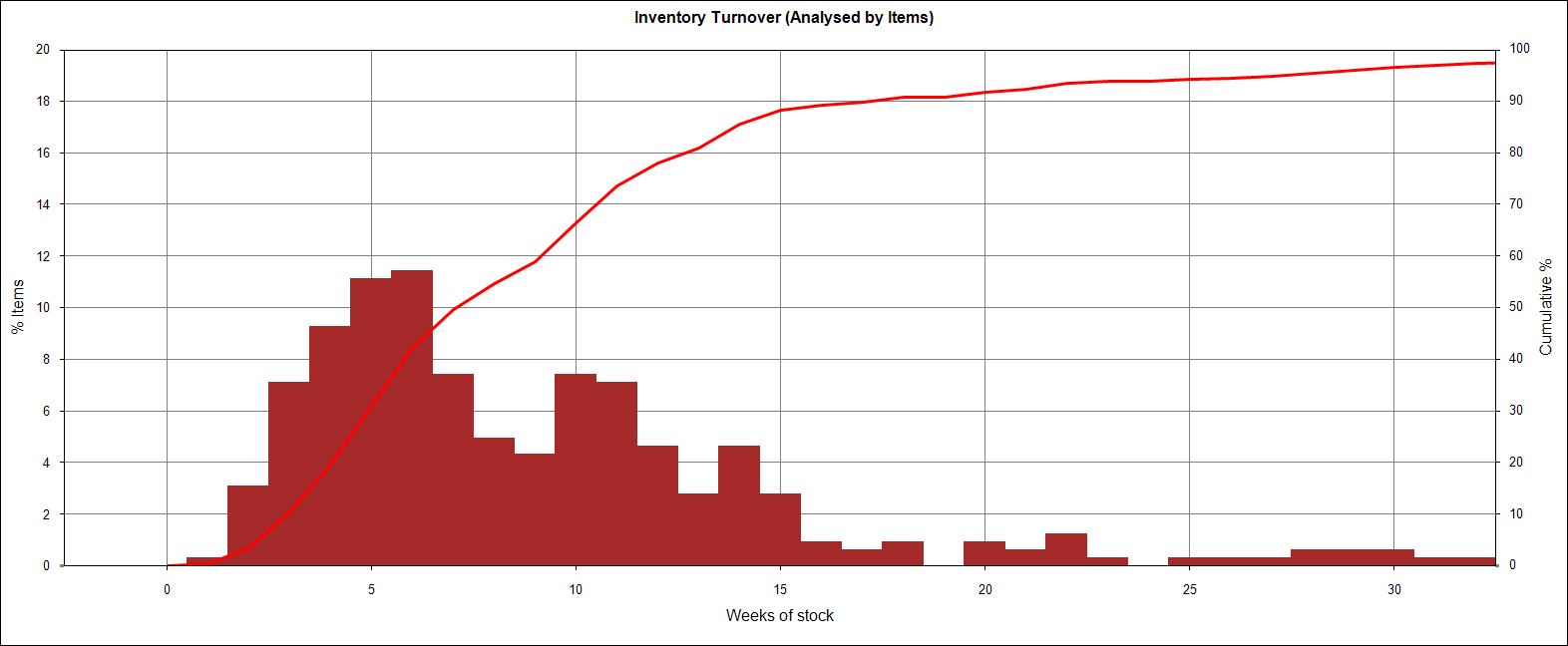

Why Weeks Of Cover Is Just Too Weak, in the July 2018 Edition

"So how many weeks of cover does that translate to?" Sounds a perfectly reasonable question doesn't it. But is it? In the July article, find out why focusing on days, weeks or months of stock as your primary metric is not the best way to approach inventory management. Much better to set your high level objectives of service level and profitability and then let the system establish what you ought to hold. You should find that the answer will be different for every item.

Click to view

|

|

Know When To Hold 'Em And When To Fold 'Em, in the June 2018 Edition

Plan for ZERO OBSOLESENCE! Now wouldn’t that be good. Find out how in the June article KNOW WHEN TO HOLD 'EM AND WHEN TO FOLD 'EM. The article explores how you can reduce your inventory exposure as you near end of product life, and then stop ordering the product before it ever becomes obsolete, potentially saving hundreds of thousands, even millions. This article includes some of the content which was presented at the very successful Autocare 2018 conference by John Allen from Horizon Inventory and Cameron Dodd from the Auto Parts Group in early May.

Click to view

|

|

Cart Before the Horse, in the April 2018 Edition

I know you would never do it, but some people do. They put the cart before the horse and then they push things uphill thereafter. Much better if you can take a systems view, and model before you make or buy a new supply chain or warehouse. See how it ought to be done in the April article.

Click to view

|

|

Good Strategies take some Digging, in the March 2018 Edition

Developing good business and inventory strategies can take some effort. You have to be prepared to dig and often to turn over long held beliefs. Find out more in this month’s article.

Click to view

|

|

Scaling the Heights, in the February 2018 Edition

When climbing a rock face or a mountain someone has to lead. The same is true in the aftermarket space. Perhaps not as physically demanding or precarious as a being roped together on a cliff, but challenging nonetheless. One thing you also learn as a climber is that freezing on the rock face for too long can sap your energy. Staying in the one place is not really an option. The same is true with your supply chain and inventory. With climbing you cannot progress unless you let go of where you are and have been. If you want to step up you have to make the right moves. Find out more in this month’s article.

Click to view

|

|

Milking the Data Cow, in the November 2017 Edition

We are living in a world rich in information – data is driving the way we’re doing business, the way we shop, the way we travel and the way we educate our future generations. We are all familiar with terms such as business intelligence, analytics, big data, KPIs etc. in our working life, but do we really make the most out of these concepts and take full advantage of the data we have at our fingertips?. Find out more in this month’s article.

Click to view

|

|

The Right to be Wrong, in the October 2017 Edition

It is very easy to beat yourself up if you are in the aftermarket inventory game. It is all too easy to be wrong. Ultimately however beating yourself up over small details and small losses will lead to poor performance. Maybe it's time to step back and look at how you can land more telling blows, more often. Find out more in this month’s article.

Click to view

|

|

The KISS Principle, in the September 2017 Edition

KISS as everyone knows stands for "Keep it Simple, Stupid". Unfortunately KISS also can be used on occasion to avoid confronting the real issues with an inventory management process or the real causes of why you continue to have excess stock. Find out more in this month’s article.

Click to view

|

|

Telematics Can Lead You to Better Inventory Levels, in the August 2017 Edition

When do we need a part in stock? Well the simple answer is when it is needed. The key now and in the future is when do we know that the part is needed, and where, and in what quantity? With apps and telematics becoming more available to help give you earlier visibility of when stock might be needed can you afford to ignore this extra intelligence?. Find out more in this month’s article.

Click to view

|

|

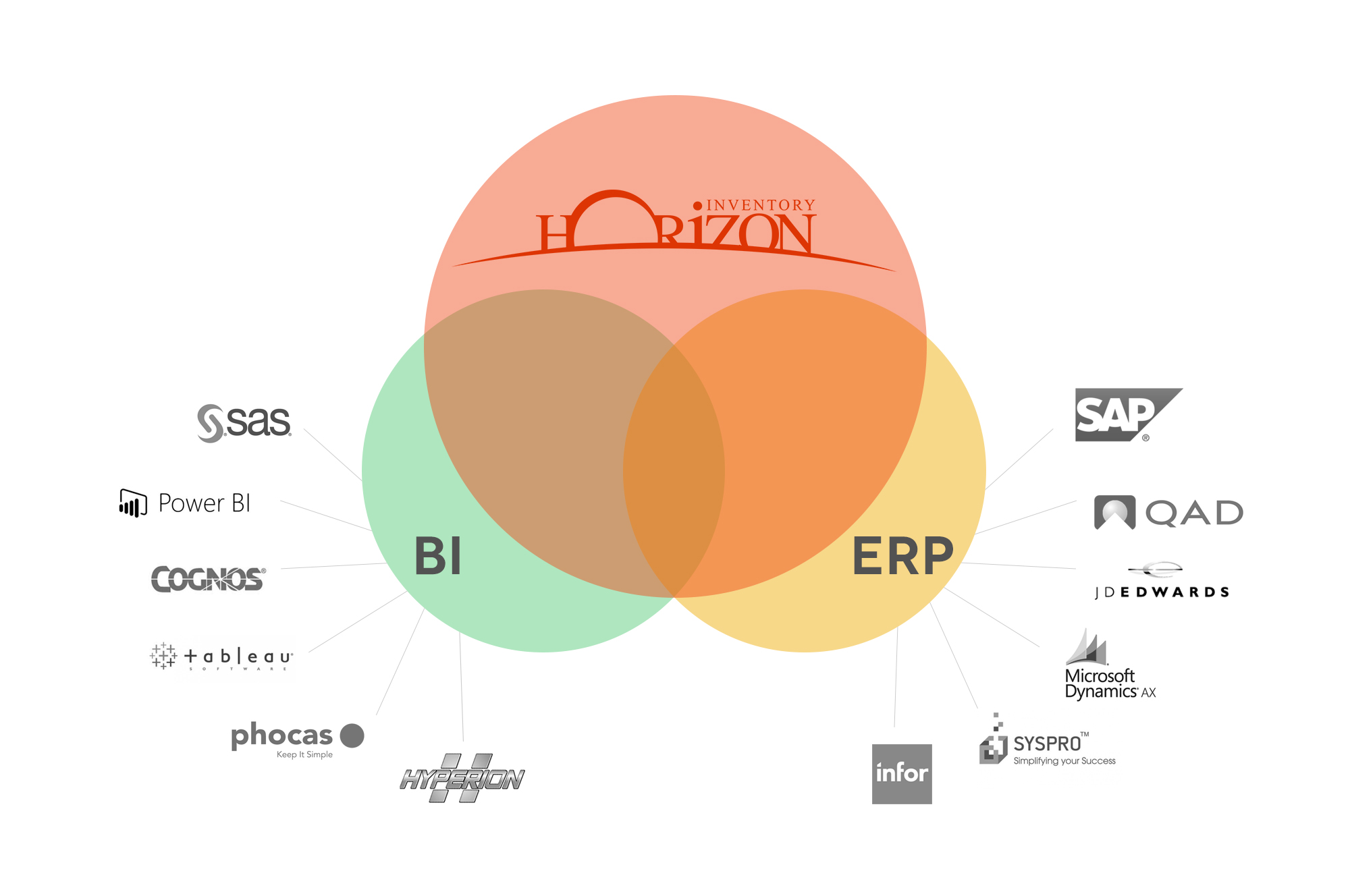

Why HI is not BI, in the July 2017 Edition

Inventory optimisation and business intelligence are 2 of the tools you can adopt and utilise in order to improve your inventory holding. Each one has it's strengths and weaknesses, but the main question one should ask is what solution would best suit me and my business, and which solution will best solve my inventory problem?. Find out more in this month’s article.

Click to view

|

|

Joining the Dots, in the June 2017 Edition

Establishing how to best source and distribute products through your supply chain can present many challenges. What if a product has high domestic transport costs, suggesting importing by sea as the best approach, rather than importing and then transferring via the internal supply network? Lots of decisions! They can be hard to make. Dynamic Supply Chain Reconfiguration can allow you to optimise the supply chain approach for every part. You can have different decisions for each part. It can be a lot easier to join the dots, than you might think. Find out more in this month’s article.

Click to view

|

|

When Track Conditions Change, in the May 2017 Edition

To maximise the chances of winning, an F1 car has to be set up just right. You need to balance the way all parts of the system operate together. Similarly if you are setting up your inventory system, you want to tweak your settings so that each item is set up just right at each point over time. Find out more in this month’s article.

Click to view

|

|

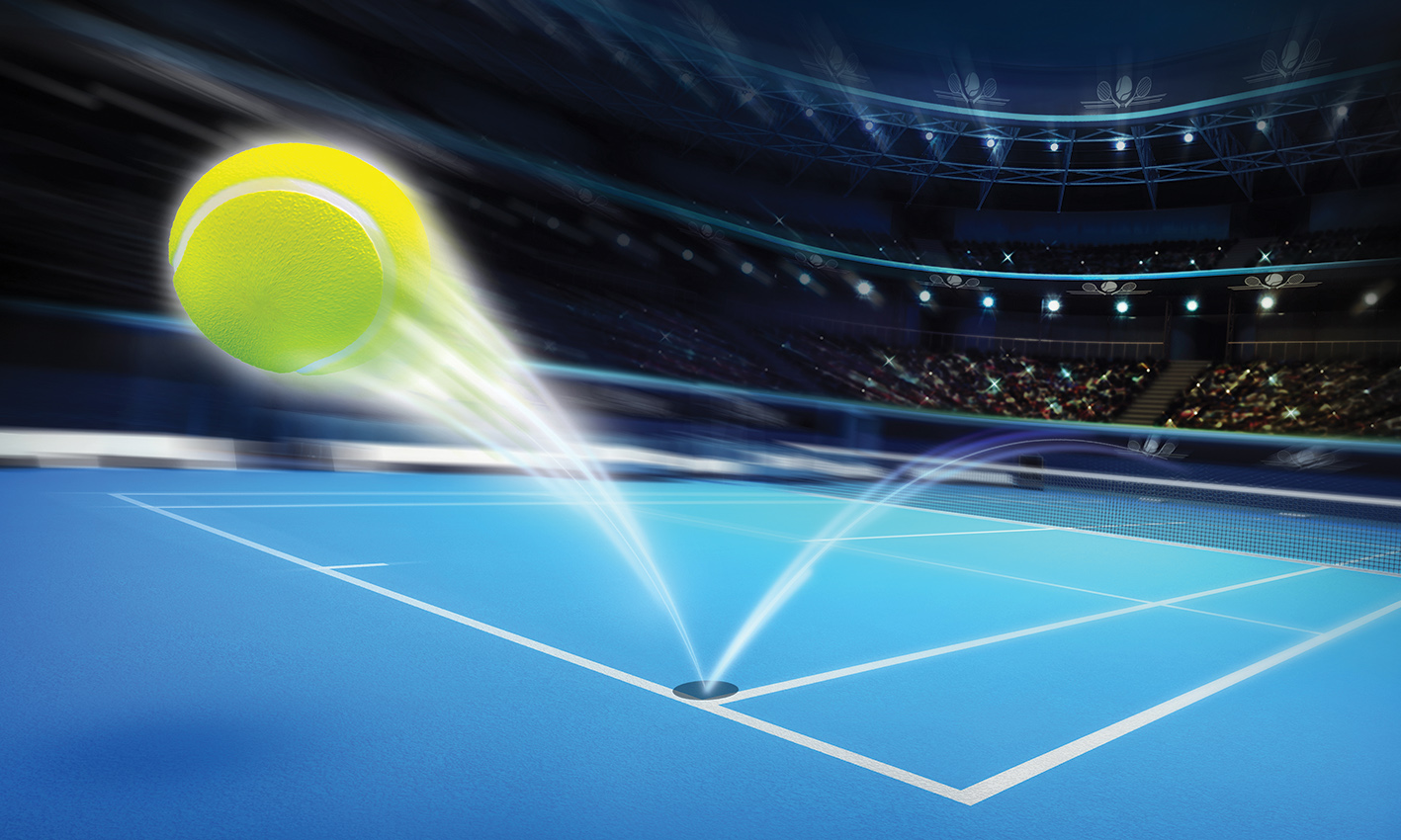

Tennis Lessons, in the March 2017 Edition

Anyone for a Tennis Lesson? Or rather a Lesson from Tennis? Find out how close to the lines you can go when you make the trade-offs between service levels and risk. This subject is explored by looking at some interesting statistics from the recent Roger Federer and Raphael Nadal Australian Open Final. Find out more in this month’s article.

Click to view

|

|

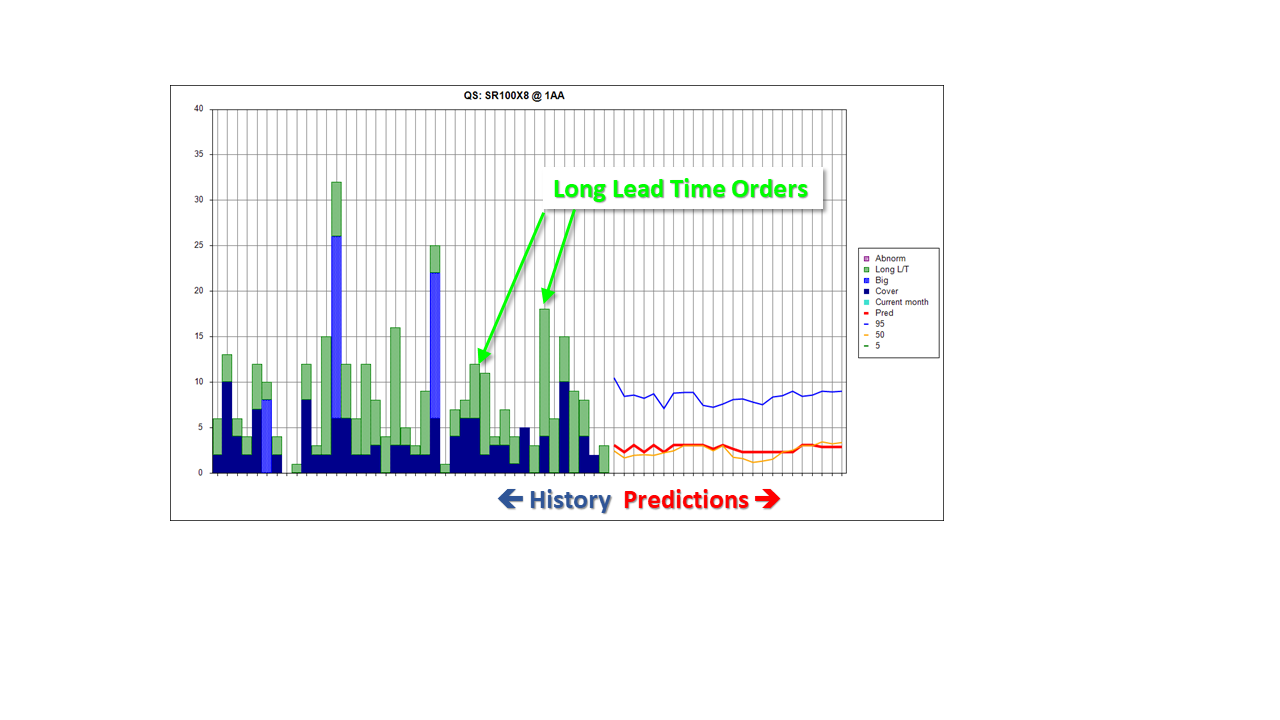

Forecasting slow movers, in the February 2017 Edition

Discover in this month’s article how the priority for slow movers is often not about improving Forecast Accuracy to the nth degree, but rather more about how you choose to stock the optimum quantity, and how you can do that easily for tens of thousands of items.

Click to view

|

|

Time to stand Inventory Management on its head?, in the November 2016 Edition

Inventory management is replete with lots of tried and tested practices, which are often rusted onto the framework of the way people run their businesses. They are very difficult to shift and can be very difficult to change. Unfortunately this seems to be especially true in Australia. It might be time to look at things anew and really challenge the status quo. Find out more in this month’s article.

Click to view

|

|

Culture Wars, in the October 2016 Edition

Why is it that some people can seem to work against each other and the organisation's objectives? The answer is often simple. They can! These negative behaviours can become embedded in the DNA of an organisation, and some behaviours can have such negative effects as to seriously damage profitability and return on working capital. Why worry about business models and strategies when you are in the inventory part of the business? Well that is it really – you are 'part' of a business and it is important to understand how better inventory management can contribute to the overall business. It all has to hang together. Better software and processes can of course make it far easier to translate better strategy into better policies, processes and practices. You can create the time and space to win your culture wars, not against the rest of your organisation, but with them. It all starts with leadership. Find out more in this month’s article.

Click to view

|

|

Let's be Gentle with Each Other, in the September 2016 Edition

The Bullwhip effect was first described in the 1960s. It refers to the amplification of variability as you go up the supply chain, further away from the original demand signal. The bullwhip effect can easily lead to overstocking by 40-50% and more. If it has been known about for so long, why is it that organisations and supply chains continue to exhibit such damaging behaviours and effects? Find out more in this month’s article.

Click to view

|

|

Teamwork - It Takes All Kinds, in the August 2016 Edition

Isaac Newton said "If I have seen further, it is by standing on the shoulders of giants.". It is a recognition that even Isaac Newton, one of the greatest thinkers of all time, cannot stand alone. He built on the achievements of others. When we look at a supply chain or inventory management system we may not have or need the same calibre of thinkers but we do need to build on and with the work of others. We need to build on the skills, knowledge, capabilities and personalities of all the people who manage and operate the processes and systems. Find out more in this month’s article.

Click to view

|

|

Swings and Roundabouts, in the July 2016 Edition

Variations in demand are little like swings and roundabouts. The variations in demand at a branch level can be very high, but at the DC level they can be much less. That suggests that you carry most of your safety stock at the DC level. But how much? You need stock at the branch to handle short term fluctuations. Where do you get the right balance?. Find out more in this month’s article.

Click to view

|

|

Mastering your Inventory System and Data, in the June 2016 Edition

As a skipper at sea you feel a lot better if you know that your boat is properly set up and everyone knows what to do if something out of the ordinary should happen. Being comfortable only happens with careful and deliberate preparation. If you get it right, you can engage the auto-pilot and just perform periodic checks to make sure you are keeping on course. Steering an inventory management system can be very similar. Find out more in this month’s article.

Click to view

|

|

Counting the Cost of Inventory, in the May 2016 Edition

When you add up all the components of cost involved in managing demand, supply and inventory it is very easy to see that your organisation can spend 10-20% of revenue across these processes. Is the 'stuff' getting on top of you, or are you focused on the right stuff? Find out more in this month’s article.

Click to view

|

|

|

Inventory Myths, in the March 2016 Edition

What are the myths surrounding inventory in your business? Perhaps it is time that they are debunked. Find out more in this month’s article.

Click to view

|

|

Actionable Information, in the February 2016 Edition

When you are trying to juggle a lot, it is too easy to make bad decisions. This month’s article focuses on what do you need to have in order to have quality, timely information that you (or your systems) can act on.

Click to view

|

|

Effective Inventory Management, in the November 2015 Edition

Our latest article explores how to stack up your benefits and balance the returns from your inventory and inventory management investment.

Click to view

|

|

Emotions Affecting Your Inventory, in the October 2015 Edition

There are a lot of things to be afraid of when we manage inventory. However we can harness the fear to produce much better outcomes. This month’s article focuses on the hard side of the soft stuff... the emotions that can drive our inventory management practices.

Click to view

|

|

Be Careful What You Measure For..., in the September 2015 Edition

We all know the saying, "Be careful what you wish for, Cause you just might get it". When we don't fully explore the implications of our measurement and incentive systems we often stumble into traps of our own making. This article explores some of the pitfalls or collateral damage that can arise when we focus on an immediate reward and lose sight of the bigger picture. It also suggests some principles that ought to be considered when designing our measures and incentives to achieve optimal inventory and business results.

Click to view

|

|

Minimum Order Quantities - Can We Be Smart About Them?, in the August 2015 Edition

In a market like Australia, with so many different models of cars on the road, we have very large ranges of parts and unfortunately, because of our market size, many do not have high sales volumes. Things are not helped when many of these slow moving items also have Minimum Order Quantities (MOQs).

How can they be managed better? Find out more in our latest article.

Click to view

|

|

Inventory People - New Age Thinking, in the July 2015 Edition

With the advent of new software to better manage very large ranges of products it is time to stock of the skills and mindsets of the important people who drive the day to day operation of your inventory management system. The July article explores the kind of people you need to drive your inventory processes and profitability further.

Click to view

|

|

Inventory Discipline - The dos and don'ts of inventory management disciplines, in the June 2015 Edition

Discipline is essential to manage inventory well but maybe it’s time to review the discipline(s) we use and their effect. Read our latest article and see how good inventory disciplines can be liberating rather than punishing.

Click to view

|

|

Lucky Inventory - Getting better odds playing the aftermarket game, in the April 2015 Edition

Article Number Seven just had to be about Luck.

It is entitled Lucky Inventory and explores how you can give yourself better odds playing the aftermarket game. The article demonstrates how you can give yourself a much better chance of having the right amount of stock, and maximise your winnings.

Click to view

|

|

The Excess of Evil..., in the March 2015 Edition

The Excess of Evil: Lurking in the dusty recesses of your warehouse could well be the seeds of your profit destruction. You can work hard to accumulate profit but one mistake can dash all your hard work. This next article explores the issue of excess inventory, why it happens and how you can avoid it and how you can better manage it. If you can put together the right processes, people and systems you can keep the Evil out of your Excess and maximise your profits.

Click to view

|

|

Matched Items - Is there a catch?, in the February 2015 Edition

You know to replace a water pump you need some other parts, but does your inventory management system? This article focuses on using the information inside your ERP system to look at the combinations in which products are used or bought. Knowing this could well affect the inventory performance for a substantial number of products. Matched Items goes well beyond the traditional kitting approaches with which you might be familiar. Can you afford to not have this sort of insurance?

Click to view

|

|

2 4 6 8 - What do we appreciate?, in the November 2014 Edition

The quantity in which an item is used will often be far more important than the predicted rate of consumption. For example, if we now say that the product is sold at a rate of 0.75 units per month, and in quantities of two each time, then you would stock 2 or possibly even four. If it was sold at just 0.25 units per month, but still in twos, then you would still stock two. You can see that it makes a lot of sense to understand and use the common quantity in which an item is being sold or used, to determine the optimum inventory holding.

Click to view

|

|

Information to Manage your Inventory, It's all there, in the October 2014 Edition

If your inventory management is not running as well as you would like, you will probably find that it is not going to get better by itself, and that your ERP system already contains much of the information you need. However you do need the right tools and different ways of understanding what is needed. You might want to look at this information asset a bit differently. How much more value can you extract from it, especially if you maintain it well.

Click to view

|

|

‘WHY MANAGE INVENTORY’, in the September 2014 Edition

Clearly there are many variables to consider when managing inventory, ranging from your business strategy and imperatives, to the effort you put into forecasting, to how well you manage product transitions and to the way you trade-off freight and buy-breaks against processing and holding costs. In fact there are usually more than twenty variables to consider if you want to get close to having your cake and eating it too.

Click to view

|

|

FOCUSING ON THE ‘WHY’ IN INVENTORY’, in the August 2014 Edition

John Allen, a founder of Horizon Inventory and thought leader in the ground breaking methods Horizon is making use of to optimise inventory for our clients discusses the reasons why holding the optimum level of inventory is important.

Click to view

|