How can I significantly reduce emergency orders by matching items in my inventory?

What happens when inventory is NOT matched?

A typical conversation in a store …

How often does a similar conversation play out in one of your sales branches or retail stores? It mightn’t be a camera and a special lens. It might be a bearing and a seal. It might be a nut and a bolt. The mouse to go with the laptop. The staples for the stapler.

Why can’t customers buy things in the combinations we determine? In the ‘kits’ we have on the shelf?

Of course when potential customers come into the store they often know what they want and need. They have something to repair or fix and need items A, B and C. If you have A and B but not C, you can get C in but this means:

- The cost of ordering and time to follow up the emergency order

- Air bag and courier charges (a concern, even if the customer pays)

- The inconvenience to your customer, and damage to your service reputation (and in turn your gross margins)

- Loss of sales staff productivity

… all because your inventory was not ‘matched up’. Maybe kitting can help?

Kits and Matched Items Compared

One solution to ensuring you have the right inventory can be the use of Kits. However Kits, while an important capability falls far short of the potential of a genuine matched item capability.

| Issue or Feature |

Kits |

Matched Items |

| How created? |

Normally created via a Bill of Material or Kit Configuration table or similar administered by a Product Manager. This involves expertise, time and effort. |

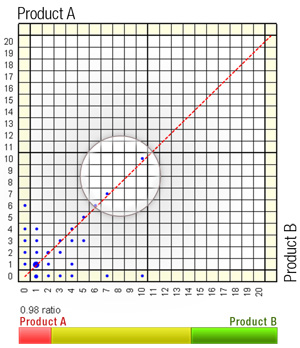

Matched Items recognise patterns in retail sales orders whereby customers are buying / using products in particular combinations. Experience has shown that micq-if’s Matched Item capability often recognises significant relationships of which ‘experts’ were not aware. Customers often have a habit of using products in ways other than those that might have been anticipated. |

| What are they? |

A kit is a product which is a fixed combination of certain components. For example you might have a kit with one bearing and two seals.

Kits can be assembled only at the point someone places an order or else they can be pre-assembled and placed on the shelves ready for sale. |

A matched item is more flexible than a Kit and describes situations where it is not mandatory that one component is bought or sold with another. For example a matched item could be composed of two or three items which are mostly sold together but are occasionally sold separately. You buy the stapler and the staples initially but thereafter you only need the staples. |

| How accounted? |

Where kits are placed into inventory in their assembled form (according to the forecast for the kit), they are usually counted by how many complete kits are in stock. If a component has been assembled into one kit, it cannot also then be made available in another kit unless you ‘cannibalise’ the original kit … but then of course your inventory integrity suffers. |

Items are accounted for at the component level, so you can mix and match dependent on whatever the end customer wants to buy or use. Matched Item inventory planning means that min-maxes are set based on expected sales / usage of the matched item set and its components, but the usage / sales does not have to conform exactly to that plan i.e. there is some flexibility. |

| How are inventory levels set? |

For any kits that are assembled ready for sale, min-maxes are separately identified for each kit. They will be separate to any min-maxes for the components when sold individually. Because the variability of individual kits is often greater than the variability of underlying components, especially more common ones, extensive kitting tends to raise inventory levels. |

Component inventory levels are set based on their demand when sold individually or when sold together in matched item sets. The idea is to ensure you are best placed to service the end user demand, in whatever form it takes. Typically overall levels are lower simply because of some fundamental statistical principles. |

Kitting can be a solution some of the time, however analysis from one situation with over sixty stores and thousands of products highlights that:

Only 6% of items which were identified as members of matched item sets had overlaps sufficient to even consider the possibility of kitting. Matched Items can typically support over ten times the products that a conventional Kit capability can reasonably manage.

and …

of the top 35,000 items sold, 10% were in matched item sets but the items in the matched item sets represented some 30% of sales – important to get the range right.

How can inventory be matched and managed?

micq-if can help you recognise and track matched item sets. You typically only require monthly analysis at most because micq-if will bring significant patterns and any changes to your attention. With a small amount of effort you can review and set matched items for your entire sales network, because after all, the stapler will use the same staples irrespective of where it is sold, the photography enthusiasts will want similar combination of lenses across the country and machines will still wear out and need to be repaired in similar ways irrespective of whether they are in Melbourne, Auckland or Singapore.

micq-if can help you recognise and track matched item sets. You typically only require monthly analysis at most because micq-if will bring significant patterns and any changes to your attention. With a small amount of effort you can review and set matched items for your entire sales network, because after all, the stapler will use the same staples irrespective of where it is sold, the photography enthusiasts will want similar combination of lenses across the country and machines will still wear out and need to be repaired in similar ways irrespective of whether they are in Melbourne, Auckland or Singapore.