Far Better Range Management

When you are managing the vast range of products that we do it is important to make the right ranging decisions. There are many factors to consider.

micq-if represents a significant advance over other inventory solutions. Its ability to tailor the inventory levels and range decisions from one situation to another means that we can achieve far better returns from our inventory investment.

Fred Bevis,

Finance and Admin Manager

BSC runs a network across Australia with over 40 branches. It sources products from over 200 suppliers and it manages a total range of over 100,000 items. Clearly it cannot stock every item in every branch. micq-if helps BSC make the right decisions as to which products to stock in what quantities in which branches.

A significant advance over "One Size Fits All"

A lot of inventory management solutions embody some overly simplistic techniques such as working out a monthly average over the last twelve months and then stocking say, one month of sales or two. You might dress this up with perhaps some forecasting and perhaps some manual adjustment of the weeks or months of sales to cover, but inevitably this just adds a lot of administrative overheads and simply cannot match the discriminating inventory management of micq-if.

BSC services many different industries across the country. It also has different supply chain approaches for different suppliers. A one size fits all approach simply would never work. Instead micq-if helps BSC manage many different situations including:

- BSC’s inventory settings automatically consider the different levels of supply risks for products supplied to branches directly by suppliers as opposed to via the national DC.

- High volume products clearly warrant higher service levels, however BSC can optimise the investment based on factors such as the order rates, the gross margins, the relative costs of normal replenishment and emergency transfers and the carrying costs, which can vary by product class, branch location etc.

- Depending on the customers being serviced, what might be considered as abnormally high sales in one branch might be just ‘average’ in another.

- Low margin or low cost products often need to be managed very differently to high margin or high value products.

- What happens if you have a product that is very popular across the network but perhaps a bit less popular in a few branches. Do you carry a lot in those branches or just enough to help a customer who might walk in?

All these different situations do not require extensive and expensive item by item reviews. Instead with micq-if, BSC has defined some policies and rules which guide the inventory optimisation processes used in micq-if … and the results in terms of return on working capital, better inventory turnover and emergency stock transfer reduction are achieved without a lot of staff time spent in onerous product reviews.

Surely it was not that easy

It was not all plain sailing though. When your inventory planning is much better, you absolutely must match it with consistent performance across the supply processes. micq-if’s ability to help us measure and demonstrate the effects of any fall off in process performance has certainly helped us focus everyone on getting not just the inventory planning right but also the operation of our purchasing, warehousing and replenishment processes.

Fred Bevis,

Finance and Admin Manager

Reducing inventory levels and getting things ‘just right’ relies on certain process assumptions like replenishment frequencies and delivery time frames. What happens if these are not met in practice? Missing a couple of replenishments because of a stocktake or leaving some stock on the floor for a while can introduce problems. Emergency stock transfers and customer impacts will be the inevitable result.

micq-if not only helps you optimise and quantify what should happen, but it has facilities to help people appreciate the importance of matching the plans with the physical execution.

So what’s new in micq-if that has helped?

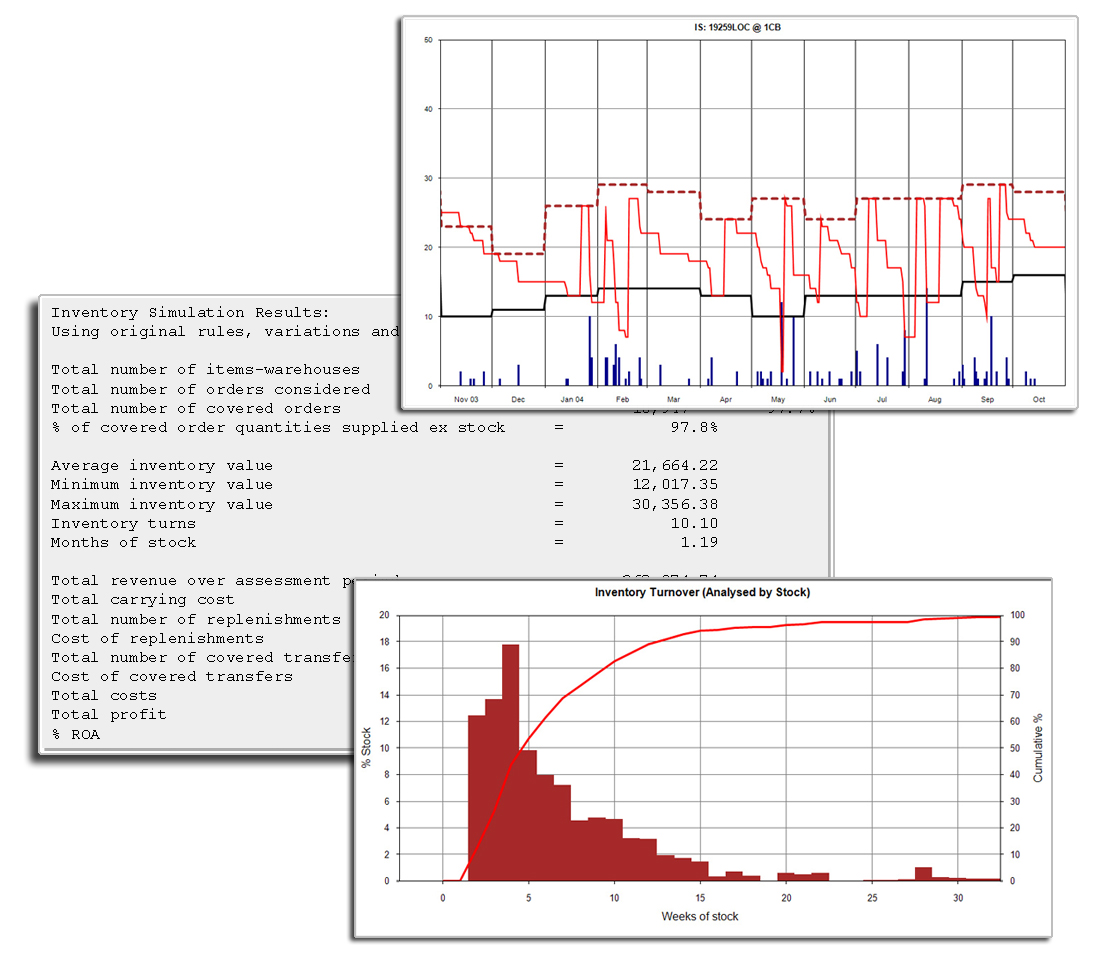

Probably the biggest recent innovation in micq-if is the Levels Tuner. It is easy to use and can help us tweak rule settings when business conditions change. It also helps us objectively measure the potential effects of changes in policies, so we can be even further ahead of the game.

Brett Bartholomew,

Group Logistics Director

The new Levels Tuner is designed to help tune inventory management policies across different categories of products across multiple branches. Just some of the things it helps you do include:

- Adjust various cost and margin rules and see their effects

- Assess the value (or otherwise) of any manual overrides

- Adjust service levels, profitability and ROA in different situations

- Assess the levels of regular replenishments versus (higher cost) emergency transfers and the value of stock holdings

- Help guard against excess inventory building up

- Help make properly informed decisions that consider service levels, profitability, inventory investment and ROA

- Easily focus on the bigger picture without being mired in the detail, but at the same time handling the detail and the variations in ways that other ERP and DRP approaches simply do not match.

It certainly is something that helps us stay ahead of our competition

Brett Bartholomew,

Group Logistics Director